Premium Lubrication System

01

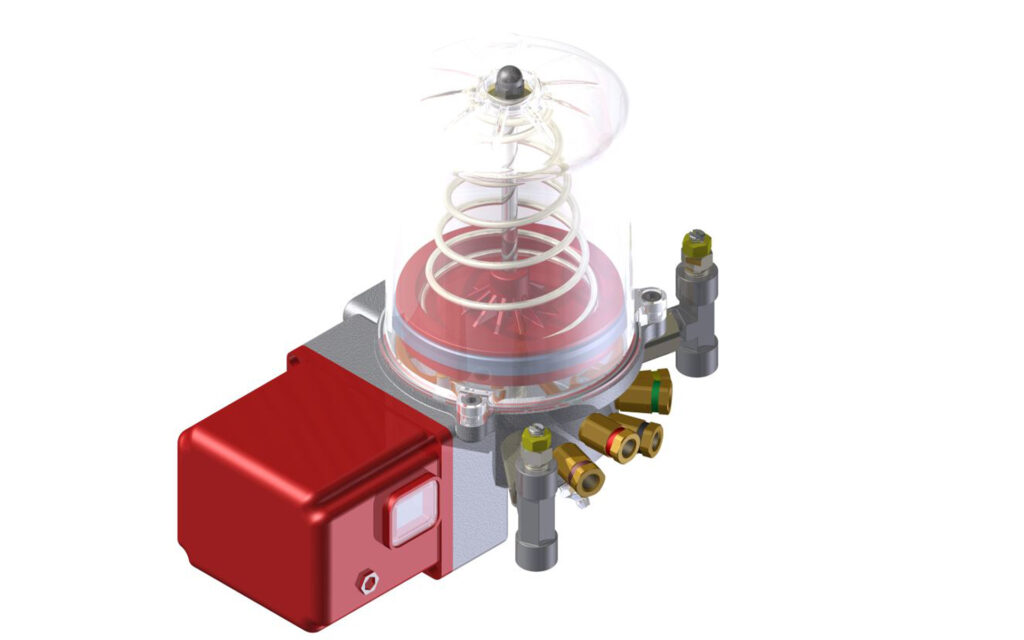

Pneumatic Single Line 210

Parallel systems enhance your preventative maintenance program and keeps your greaseable components in excellent condition—resulting in safe and reliable equipment performance. This innovative pump design provides lubrication of critical points such as pins, bushings, lift cylinders and articulation joints.

ddd

02

Modular Progressive

Parallel systems enhance your preventative maintenance program and keeps your greaseable components in excellent condition—resulting in safe and reliable equipment performance. This innovative pump design provides lubrication of critical points such as pins, bushings, lift cylinders and articulation joints.

03

Multi-Line “Spyder”

The Multi-line “Spyder” pump’s all-in-one design provides a low-cost solution with big maintenance savings. It will enhance the safe operation of your equipment by delivering continuous lubrication to critical components such as automatic brake adjusters, clevis pins, spring hangers, linkages, lift cylinders, turn tables, fifth wheels, etc.

04

HP-400 Compact Chief

The HP-400 Compact Chief Lubrication System’s compact footprint ensures your small equipment remains well lubricated. Its simple design delivers a precise amount of grease, allowing for consistent delivery with every cycle of the equipment.

05

85:1 class Air Grease Pump

85:1 class Air Grease Pump is a specialized tool used in various industrial applications for lubricating machinery, equipment, and other mechanical components. The “85:1” ratio refers to the compression ratio or amplification factor that the pump provides.

06

50:1 class Air Grease Pump

50:1 pressure air grease pump is a specialized lubrication tool designed to deliver grease at high pressure using compressed air. It’s commonly used in industries such as manufacturing, automotive, and heavy machinery maintenance to ensure smooth operation and prolong the lifespan of equipment.

07

Compact Grease Pump (1KG, 2KG)

COMPACT GREASE PUMP is an electric grease pump ideally suited for lubrication equipment, buses, heavy equipment, industrial machinery, automation systems, and small and medium-sized lubrication systems.

Contact Lubecore – Korea

Address : 15, Seobu-ro 123beon-gil, Jinyeong-eup, Gimhae-si, Gyeongsangnam-do, Republic of Korea

Tel : +82 – 055 – 342 – 4656

FAX : +82 – 055 – 342 – 4866

Phone : +82 – 10 – 3128 – 9558

E-mail : TAESUNGCO@TAESUNGCO.KR

CHLEE@TAESUNGCO.KR